Te Mato Vai: PACl on Trial

Te Mato Vai: PACl on Trial.

Compiled by: Andy Kirkwood, Justine Flanagan. Dec 2019.

[www.islandbooth.com/comm/191204-pacl-on-trial.html].

Contact: [firstName] @ islandbooth.com.

Masthead Te Vai Ora Maori Protest; Matavera, Rarotonga, 2 Dec 2019. Collecting only clear water and diverting the muddy water, means that coagulation chemicals will not be required.

This is a working draft. Published 12 Dec 2019. Updated 19 Oct 2020.

As part of the Te Mato Vai Project - Stage 2, the Government of the Cook Islands has constructed water treatment facilities. These include chemical-treatment systems to coagulate and disinfect the public water supply.

On this page

- Turbidity: Water Clarity

- Watercare Raw Water Quality Review

- Microbial Quality: Water Safety

- Rinse, Repeat

- PACl Trial

- Environmental Impact Assessment: Necessary Precaution

- Long-term fate / Chemical Lifecycle

- Recommendations – Not Undertaken

- ‘International Practice’?

- Cook Islands Legislation

- Conclusion: Divert

- Appendix A: PACl EIA Terms of Reference

- Appendix B: PACl Trial Unpacked

- References and Further Reading

Turbidity: Water Clarity

The new Te Mato Vai system proposes a four step treatment process. Step 2 is (chemical) coagulation/flocculation.

[Coagulation] Removes small particles and protozoa

This is a slow mixing process. It uses a ‘coagulant’ called polyaluminium chloride (PACl) to make small bits of dirt etc. stick together and settle at the bottom of the [settlement] tank.

This step, together with filtration removes harmful protozoa (for example giardia).

-Improved water will soon flow through our new water supply system.

Cook Islands Government Release in Cook Islands News, 30 Nov 2019.

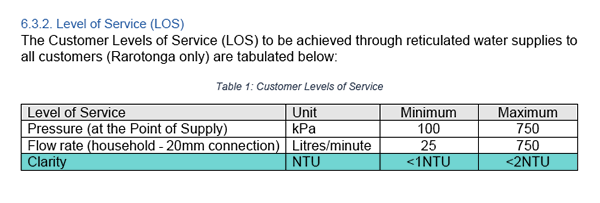

Watercare Raw Water Quality Review (2014)

In 2014, Watercare New Zealand established a laboratory facility in Rarotonga to test raw/source water quality at the (then) 12 water intakes.

It is evident in the results that apparent and true colour increases during a rainfall event. A form of treatment to remove colour from the raw water would be required e.g. coagulation, or there needs to be the ability to divert any water that does not meet the required standard.

-Watercare 2014

Cultural preference (as evidenced by technical reports, household surveys, public consultation, etc.) is for non-chemical water treatment methods. A method identified by Watercare is to ‘divert any water that does not meet the required [clarity] standard’ — diversion systems do not require the use of coagulation chemicals.

Diversion is the option that the government of the Cook Islands should be trialling to achieve clarity standards.

Waterflow conditions

The three flow conditions that impact on water quality are described in the Watercare report as dry weather, wet weather, and after rain.

In addition it can be argued that baseline data is also required on stream chemistry in sustained dry conditions; times of low-, or no-rainfall where the streams are feed only by ground water.

Above: Rarotonga Raw/Source Water Quality Analysis (2014). Adapted from source to highlight turbidity measurements. For effective UV disinfection turbidity should be under 1.0 NTU. Source: Te Mato Vai Project Raw Water Quality Review Rarotonga (2014). Watercare New Zealand.

- Only seven intakes were tested during wet weather conditions.

- In dry weather, 7 of the 12 intakes provided ‘clear’ water before any treatment/filtering: turbidity ranging from 0.50-1.0 NTU. A further four intakes were just outside of the required standard for UV disinfection at 1.2-1.4 NTU.

- The 2017-2019 Te Mato Vai upgrades include new coarse filter intake screens, 3-hour settlement tanks, and sand filtration. These are physical, non-chemical treatment methods that will further improve water clarity.

- No test results have been released of water quality after (only) physical processing by the new Te Mato Vai system (but without chemical treatment). On inquiry, GHD does not intend to carry-out any testing to establish a baseline against which to assess the efficiency (or need) for coagulant chemicals.

TVOM: To confirm — there is no intent to collect control data on the effectiveness of the new Te Mato Vai treatment system prior to commencing the operational use of PACl?

GHD: The TMV system is designed to reliably achieve WHO potable water standards, under a wide range of current and future site conditions. The Watercare data already provided was sufficient to inform design to achieve this standard — there is no other ‘baseline’ data.

-July 2020

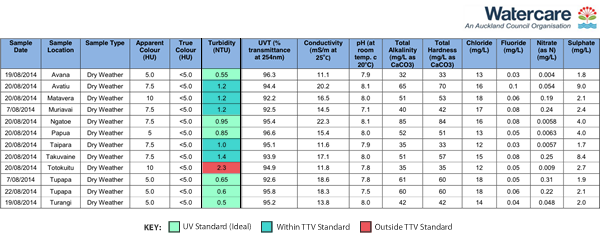

To Tatou Vai Level of Service

The new water authority’s code of practice sets a clarity/turbidity target of under 1.0 NTU; but with a tolerance of up to 2.0 NTU. Based on the TTV standard, of all the intakes tested by Watercare in dry conditions, only Totokuitu might require supplementary treatment / use of coagulation chemicals. (And turbidity levels might be sufficiently reduced by the physical filtration processes.)

Above:To Tatou Vai Clarity service levels Source: To Tatou Vai: Code of Practice for Design and Construction of Water Supply Infrastructure. Aug 2019. To Tatou Vai Ltd.

Above: In dry conditions, and without any treatment or filtration, only Totokuitu falls outside of the To Tatou Vai level of service clarity standard maximum value of 2.0 NTU.

Microbial Quality: Water Safety

The purpose of water disinfection is to reduce the risk of illness due to the presence of pathogenic microorganisms in the water. An increase in the number of microorganisms in drinking water is often linked with high-turbidity events: wet weather/heavy rain when organic matter is washed into waterways.

Given the highly variable turbidity it is likely that there would be a significant risk of microbial pathogens present in the water supply. Upon request from GHD Ltd microbial tests were not undertaken by Watercare Laboratory Services Ltd. As a result an assessment of compliance with DWSNZ for microbial parameters (bacteria, viruses and protozoa) cannot be made…

-Watercare 2014

Increased turbidity also impacts on the effectiveness of disinfection processes. This is true for chemical and physical disinfection methods (such as UV irraditation).

If UV disinfection was to be used, then at turbidity levels greater than 1 NTU, this process can be hindered through shielding of microorganisms by suspended particles. In order for disinfection treatments to be effective it would be necessary to undertake a form of solids removal such as coagulation to reduce turbidity to < 1 NTU.

-IBID

UV is a non-chemical disinfection method. Installation of UV filtration systems into residential homes would ensure the safety of water ‘at the tap’; even as work continues on the replacement of the water main through the first half of 2020.

Rinse, Repeat

November 2019 a further report was prepared by the water engineers on the use of PACl.

All parameters including colour and turbidity are marginal as to whether the water needs to be dosed with coagulant for colour during dry weather conditions. However, due to the speed of change of flows (and resulting sediment loading) it is likely that to achieve a consistent output (without powered monitoring devices and control), coagulant will be required most (if not all) of the year. The decision to treat all of the water all of the time is to optimise water quality (the sedimentation tank will not be needed for consistent periods of dry weather and the AVG would be kept operational).

-GHD, Nov 2019

‘All parameters including colour and turbidity are marginal as to whether the water needs to be dosed with coagulant for colour during dry weather conditions… the sedimentation tank will not be needed for consistent periods of dry weather.’

-GHD, Nov 2019

As with the Watercare recommendation, GHD also note that in dry conditions coagulation chemicals are not required; the need for chemical treatment is ‘marginal’.

Although there is no mains power to the intakes, the proposed chlorine-disinfection dosing system is to be powered by rechargeable batteries. A similar strategy could be employed to power ‘monitoring devices and control’ — to stop streamwater collection when turbidity does not meet the required standard. LED-based turbidity detection units are marketed as highly energy-efficient.

The total stored supply provides an estimated 2-3 days of reserve water. Along with the the new 1.8 and 2.2 million litre storage tanks, the water in the settlement tanks and AVG sand filters is also available until collection can resume. The same provision that has been made to maintain supply in drought conditions, will provide supply over times of deluge.

Engineer Ross Dillon who is overseeing training in the operation of the new Te Mato Vai systems advised that the stream water clears within 3 hours of rain at the intakes. This is the case even when the streams may still be clouded in coastal areas. Once streamwater turbidity returns to an acceptable level, collection at the intakes would automatically resume.

PACl Trial

‘Jar’ testing of source/raw water samples can be used to assess the effectiveness of coagulation chemicals.

Q: Flocculators : Can you explain what a jar test is?

A: Jar testing is a pilot-scale test of the treatment chemicals used in a particular water plant. It simulates the coagulation/flocculation process and helps operators determine if they are using the right amount of treatment chemicals. The sample is stirred to observe the formation, development, and settlement of floc which forms when treatment chemicals react with material in the raw water and clump together.

-Flocculators. Stuart Equipment. Accessed 30 Jan 2020.

In 2014, jar tests were only carried-out at Avatiu intake; with the coagulant chemical ‘alum’ (aluminium sulfate). Jar testing of polyaluminum chloride (PACl) in wet weather conditions was recommended by Watercare but not completed at that time. Jar tests do not require PACl-dosing of the public water supply.

In order to further assess the optimum dosing range for the raw water intakes in Rarotonga it is recommended undertaking jar tests at the other intakes as well. It is also recommended that samples are taken under wet weather conditions in order to capture the ‘worst-case-scenario’ and understand to what extent coagulation will improve water quality under these conditions.

-Watercare 2014

PACl jar tests have subsequently been conducted by contractors McConnell Dowell. In Nov 2019, Te Mato Vai Project Managers GHD, referring to these tests, suggested that PACl dosing would be far-lower than is required internationally.

Above Jar testing the coagulant polyaluminum chloride.

Source To Tatou Vai: Our Water video. Dec 2019.

91. Concentration of PACl dosing in the operation of the treatment plants is expected to be far lower than the equivalent water treatment plants internationally — Typical dosing rates for PACl are generally 14-24mg/L, however, the proposed dosing rate for Te Mato Vai sites are significantly lower at approximately 4-6mg/L. This reduces the likelihood that concentrations of Al will be in excess of 0.1mg/L, but does not eliminate it.

-GHD, Nov 2019

Rarotonga’s source water is considered by the water engineers to be of exceptional clarity/low turbidity. Also note that levels of dissolved aluminium (Al) in the finished water could be in excess of the regulatory maximum accepted value (MAV) for aluminium in drinking-water: < 0.1mg/L. This is due to low-turbidity water being more difficult to dose effectively; in clear water suspended particles are further apart. Unused (residual) polyaluminium chloride will continue through to the public water supply.

36. Due to the general design of the settling tanks, even relatively low levels of PACl dosing will produce ‘good’ results for a broad range of raw water turbidity conditions. This is due to the large volume of water held in the settling tanks, which create a large ‘buffering’ capacity within the tanks that can manage rapid and large change in turbidity with relatively low PACl dosing rates, without having to adjust the dosing rates to respond to a change in conditions.

-IBID

The above proposes that PACl dosing is not critical to achieving ‘good’ water results; as stored water buffering will offset the (extreme) variability of flow conditions (see Watercare turbidity data, above).

Set and Forget?

There is no remote monitoring of conditions at the intakes. There is no direct communication, phoneline connection and cellphone coverage is not available to all intakes.

- Operators will not know when weather conditions and turbidity-levels change.

- The proposed PACl system does not automatically change chemical dosing to match turbidity.

- The majority of the intake sites are remote. Avana, one of the largest water producers requires 13 stream-crossings to access the site. During heavy rain, the conditions most-likely to require dosing to be adjusted, the intake sites

may beare inaccessible. - PACl will be ‘used-up’ in high-turbidity conditions, but will continue into the public water supply when the water is clear. Streamwater typically clears within three hours of a rain event.

Once again the Ministry of Finance’s claim of a ‘state-of-the-art’ water treatment system, falls well short of the Mark.

13.4.3 Performance and Control …coagulation/flocculation is most reliable when raw water quality is consistent, when changes occur slowly, or when adequate automation is used to respond to changes in raw water quality.

…As raw water conditions change, optimal coagulation dose rates also change and careful control is required to prevent overdosing and underdosing.13.7.4 Optimisation of the filtration process

Raw water that has high colour and low turbidity … can be very difficult to treat… These waters can result in elevated aluminium levels in the filtered water, and hence additional attention should be paid to monitoring filtered water aluminium.-Guidelines for Drinking-water Quality Management for New Zealand (Updated June 2019). New Zealand Ministry of Health, 2019. (PDF) Chapter 13: Treatment processes, coagulation

Environmental Impact Assessment: Necessary Precaution

Attending the Koutu Nui Vaka Puaikura water presentation in Oct 2019, the chair of the water authority board advised that trialling of PACl dosing was necessary to complete an Environmental Impact Assessment Process (EIA); to obtain a permit under the Environment Act 2003. However, proceeding with an island-wide six-month live trial is a poor (and unnecessary) re-interpretation of the Precautionary Principle.

a live trial puts public health and stream environments directly at risk

A live trial puts public health and stream environments directly at risk. The purpose of an EIA is to protect against potential environmental degradation; it is irresponsible to ‘pollute-first-and-ask-questions-later’.

The Cook Islands National Water Policy (2016) defines the Precautionary Principle and related issues of environmental protection.

Precautionary Principle

Taking active measures to prevent serious or irreversible environmental damage or degradation whether the consequences are uncertain or not.Sustainability & Environmental preservation

Strive to protect and avoid adverse interference with the natural ecology of the Cook Islands’ waters and lagoons and ensure that usage and management of water will be conducted in a manner that will preserve and enhance this resource for generations to come. …Mitigation of the impact of Infrastructure and Development on Ecological Flows

In designing and delivering future water supplies, infrastructure, services and operations will be provided in a manner that ensures that ecological flows are maintained in natural streams and waterways to the greatest extent practicable in order to ensure the protection of freshwater and coastal ecosystems.

Cook Islands National Water Policy (2016)

An engineering assessment will likely include evidence that — given the system employs standardised water engineering methods — the proposed treatment-method will ‘work’ to achieve drinking-water standards. However a genuine EIA would also evaluate the true cost of long-term chemical-use, such as fate of the wastes that are generated (water treatment residuals - WTRs). The operation of the new Te Mato Vai system proposes the discharge of WTRs into onsite storage ponds (lagoons), streams, and landfill.

There is now increasing concern on the impact to the aquatic environment (Helserman, 2009). The direct disposal of WTR to watercourses is now illegal (South Africa National Water Act No 36 of 1998)… Monitoring is required depending on the daily volume discharge, the specific municipal bylaws per region and type of permit granted whereby oil and grease and biotic index monitoring may also be required. Periodic discharges of accumulated sludge from settling tanks can possibly disrupt stable ecosystems more than a continuous low-level discharge.

Guidelines and Good Practices for Water Treatment Residues Handling, Disposal and Reuse in South Africa (2017)

Long-term fate / Chemical Lifecycle

The sustainability of the treatment method can be evaulated by considering the hierachy of potential waste disposal and management strategies, where preventing or minimising waste production is most favourable.

Above Hierachy of sustainable waste management strategies. Preventing or minimising waste is most favourable. Source Guidelines and Good Practices for Water Treatment Residues Handling, Disposal and Reuse in South Africa (2017)

It is also necessary to consider the operation of the water treatment facilities and the proposal to store treatment residuals onsite.

The following describes a treatment system using alum, but the same applies to PACl ponds/lagoons.

3.3.3.4 Lagoons

Lagoons are generally operated in a cyclic sequence: fill, settle, decant. This cycle is repeated until the lagoon is full or if the decanted liquid can no longer meet [regulatory chemical] discharge limits. Solids settle to the bottom of the lagoon and liquid can be decanted from various points and levels in the lagoon after a period of hours or days. The solids are then removed for final disposal. The decanted water is often returned to the head of works. … The lagoon is filled over a long-time period (approximately a year) and then allowed to dry while another lagoon is filled. The solids never really dry unless the pond is eventually drained and the solids undergo evaporation. Contractors can also be hired to dredge the wet solids from the lagoon bottom and haul them away for dewatering and disposal. Liners made of high-density polyethylene (HDPE), leachate collection systems, and monitoring wells are common features of lagoon designs. …A lagoon that is left to “revert to nature” will take a long time to dry out. After the supernatant, has been drained out or allowed to evaporate, the sludge at the surface forms a crust, giving the appearance that the lagoon is now filled with dry residue. The crust-covered lagoon can be compared with a frozen pond – the surface may or may not support the weight of a human or stock. Therefore, it is important to fence off the lagoon and to ensure that it remains fenced off. It may take many years before the waste dries out to the base of the lagoon. There will be a large amount of shrinkage during the drying out process.

-IBID

Specific issues for Rarotonga include;

- Lagoons are unlined.

- Low evaporation potential: as the lagoon surface is bunded and below ground level the surface of the pond will not evaporate effectively due to wind-action; locations have high-humidity; lagoons are often shaded.

- Stagnant water may become an insect breeding site.

- The lagoons are designed to overflow to the neighbouring stream (dissolved chemical levels are not monitored / there are no automated systems to prevent overflow if regulatory values are exceeded).

- Coagulation is used to remove material that is likley to be high in bacterial content; this material will then be concentrated in the ponds. Wash-out of the ponds will contaminate the stream below the intakes.

(The concentration of organic material is the same reason why poorly-maintained water filtration systems can result in high bacterial readings.) - The supernatant is piped to a single lagoon that is located directly below each settlement tank; there is no provision to allow a lagoon to ‘revert to nature’ / ‘dry out’.

Above Te Mato Vai: Chemical Cost.

Supply estimated at $500k (calcium hypochlorite + polyaluminum chloride). The true cost of chemical water treatment includes the disposal of water treatment residuals/waste management. Source: Te Vai Ora Maori, Submission to the To Tatou Vai Authority Bill.

‘Safe for drinking’ may not be ‘suitable for growing’

Less than 1% of Rarotonga’s water is required as drinking-water, while agricultural users represent 40% of demand.

A further environmental impact that has not been assessed (and which has been overlooked by the Cook Islands National Water Policy), is the impact of chemical residues in water that will be used for irrigation purposes.

Water that is made safe for drinking – by chemical means – may not be suitable for growing. Installing and powering filtration systems to remove residual chemicals from irrigation water may make growing commercial unviable or will result in costs being transferred to consumers. A 2020 regional pacific guideline advises that growers may need to implement an ‘intervention step’ to safeguard against chemical impacts on plant and soil health.

The GHD Nov 2019 report proposed that treatment waste could be used in agriculture. However this claim was retracted after landowners showed an interest in reusing the PACl sludge for growing taro.

TVOM: Can you direct me to the research about PACl sludge being used for gardening/agriculture?

GHD: Upon further review of the research we have found that the information does not demonstrate enough depth to reference and does not relate specifically to the local context of Rarotonga.

-GHD, July 2020.

Recommendations — Not Undertaken

Eleven recommendations were made by Watercare in 2014, including:

- Undertake a Sanitary Inspection of the Water Supply as part of a comprehensive Public Health Risk Management Plan in order to determine an appropriate treatment process to eliminate microbial risk.

- Undertake sampling and testing for microbial parameters in order to determine the public health risk associated with bacterial, viral and protozoan pathogens.

- Investigate appropriate disinfection treatment options to eliminate microbial risk e.g. chlorination, UV treatment.

- Undertake further jar tests using both PACl and alum at all 12 raw water intakes under wet weather conditions in order to establish the optimum dosing range to reduce turbidity.

- Consider undertaking selective abstraction and/or treatment if abstraction is to occur across all flow conditions.

- Investigate an appropriate form of treatment to reduce true colour.

- Sample the remaining five raw water intakes during wet weather conditions in order to establish a ‘worst-case-scenario’ of water quality at these intakes.…

-Watercare 2014

Aside from the 2019 microbial tests of the old water supply system – the first of which was commissioned by a private company – it is not clear if the Cook Islands Government has actioned any of these recommendations. Specification and construction of the Te Mato Vai treatment system has progressed without first completing adequate investigation of the source water quality.

‘International Practice’?

In December 2019 the Te Mato Vai Project Management Unit (PMU) provided reassurances to the pubic regarding the use of chemicals for water treatment.

As Te Mato Vai commissioning gets underway, we would like to highlight that the project holds all the necessary National Environment Service permits, and we have not, and will never be discharging chemically-treated water into our streams.

-Te Mato Vai (Facebook Page), Accessed 4 Dec 2019

Te Vai Ora Maori: Where does the supernatant [PACl wastewater] go?

PMU: All waste will be managed responsibly, in line with international best practise.

-IBID

‘Without a permanent power supply at each site… the supernatant is proposed to be discharged to the adjacent streams.’

However the PMU’s reassurances are at odds with engineering reports by GHD detailing how the Te Mato Vai system will operate and the process of commissioning using shock-chlorination; which includes the discharge of chemically-treated water from the 1.8 and 2.2 million litre storage tanks either into the ground or streams.

Wastewater from the coagulation process – containing dissolved aluminium – will also be discharged.

Typical WTP Arrangements using PACl (outside of the Cook Islands)

63. Without a permanent power supply at each site, [pumping to the headworks] is not possible at the Te Mato Vai sites, and so the supernatant is proposed to be discharged to the adjacent streams.

-GHD. Nov 2019.

5 Monitoring and Management Practices (Environment)

62. In New Zealand and Australia, in most cases sludge supernatant (wastewater) is recycled back to the inlet of the water treatment plant…pumping the supernatant back up to the head of the works. Only the sludge becomes waste product as the supernatant is recycled…

…So, for discharges of PACl (or dissolved aluminum) to the environment (through Supernatant), there is no ‘standard’ practice. However, we have identified one example of where sludge pond supernatant is discharged back into the environment. This is at the Wairoa Water Treatment Plant (WTP) located in Frasertown…

-IBID

Discharge of PACl wastewater/supernatant into the streams is not to an international standard; “there is no ‘standard’ practice’”.

The GHD report goes on to detail the 8-stage control conditions that have been set by the Hawkes Bay Regional Council in order for stream discharge to proceed at the Wairoa water treatment plant. These control conditions relate to comparing dissolved aluminium levels in the stream against regulatory values. The monitoring is not of environmental impacts that might have resulted from an increase in aluminium levels.

- The Wairoa plant is 28km from the sea. As one example, the Turangi stream flows into Muri lagoon less than 3km from where wastewater will be discharged.

- Rarotonga’s streams are subject to extreme variation in flow conditions. Dry-out would result in an increase in the concentration of aluminium in the stream water or build up of sludge in the streambed.

- Dissolved aluminium entering the stream will coagulate the stream water; creating a layer of sludge in the stream bed which will suffocate flora and fauna.

- The Te Mato Vai systems are located at the head of all of Rarotonga’s major freshwater streams, which then feed into wetlands, the Muri estuary, and the nearshore lagoon. The streams also flow through residential and recreational areas.

If water treatment residual (WTR) is discharged into a water body the solids can settle to the bottom of the water body potentially causing benthic smothering and the pollutants contained in the WTR can have negative impacts on the water body through re-suspension (USEPA, 2011). The increased turbidity of WTR can limit the growth of rooted aquatic vegetation by reducing the amount of light penetration available. The solids can also clog fish gills.

-Guidelines and Good Practices For Water Treatment Residues Handling, Disposal And Reuse in South Africa (2017)

Cook Islands legislation

The Project Permit for the Construction of the Te Mato Vai System was contingent on the Te Mato Vai Stage 2 Environment Impact Assessment Report (2015). The EIA report identifies the relevant legislation, policies, and standards; including the Environment Act 2003; Public Health Act 2004; and Cook Islands National Water Policy.

For an overview of the permitting regime (Environment Act) see the separate digest on the Environmental Impacts of Water Treatment Chemicals; see above for select references to the water policy.

Under the Public Health Act 2004: sludge or other by products from water treatment plants is ‘Hazardous waste’. Section 54(2)(d) “prohibits hazardous waste to be directly or indirectly deposited or discharged, or to seep, into a waterway”.

Clearly, the legislative and policy context should have been given greater consideration by GHD when specifying the treatment system. The proposed method of operation conflicts with the laws of the Cook Islands.

Conclusion: Divert

Based on the source streamwater quality, engineering reports, and the upgrades to the physical filtration of source water at the intakes, the addition of turbidity monitoring and diversions systems will likely make the use of coagulation chemicals unnecessary.

Proceeding to live trial PACl when this will require the discharge of wastes into an unbenchmarked environment, and without appropriate monitoring of the flow-through of chemicals into the public water supply would be grossly-negligent. The Cook Islands Government should instead instruct the contractor to implement and trial turbidity monitoring and diversion controls.

Appendix A: PACl EIA Terms of Reference

Announced to the public in January 2020, engineering firm GHD has prepared an Environmental Impact Assessment Terms of Reference for To Tatou Vai, the new water authority: Terms of Reference for PACL use EIA (Oct 2019) provides a structure and identifies the key considerations to be investigated by the appointed consultants.

The EIA report should use a level of analysis and detail that reflects the significance of the activity’s potential environmental impacts, and that allows the Cook Islands Government and interested stakeholders to clearly understand the activity’s likely environmental, social and cultural consequences.

To be included in the assessment are:

- Alternatives to the proposed use of PACl including chemicals, technologies, treatment processes or disposal methods. (Considering cost, and treatment and environmental outcomes.)

- A toxicity, fate and transport assessment of PACl.

- The transportation and disposal of dried sludge.

- Predicted type and quantity of waste outputs (liquid, solid and gas emissions).

- A monitoring plan, including performance criteria for measuring the extent of environmental impacts, and/or the success of mitigation measures.

- Description of the baseline environment: Sensitive environmental areas or landuses immediately surrounding PACL storage areas, the scour ponds and sludge disposal locations. Identify any high value or threatened flora, fauna or herptofauna that may be present immediately surrounding these areas.

To Tatou Vai (TTV) has commissioned the EIA. TTV is currently preparing the Environmental Impact Assessment (EIA) for the new water treatment system’s operational use of PACl. The public will have the opportunity to comment on the EIA during the consultation period. The PACl trials will provide information to inform Government and landowners’ views about longer term PACl use.

-Te Mato Vai PMU, 4 May 2020

Although openly-worded; it seems that the PMU intend to instruct the Contractor to proceed to use chemicals without a Project Permit.

[To Tatou Vai] Terms of Reference for PACl use EIA

- Feb 2020: Consulting firm Tonkin + Taylor have been appointed by To Tatou Vai to prepare the EIA submission. No ETA has been indicated for the EIA, however PACl-use trials were proposed to resume 6 Feb 2020.

- 28 Sept 2020: PACl use commenced at the Ngatoe intake. The PMU has not obtained a Project Permit for the PACl trial.

Appendix B: PACl Trial Unpacked

February 2020 the Project Management Unit and GHD released further information regarding the 6 month PACl trial in response to questions posed by Te Vai Ora Maori.

How will you monitor the impact of PACl use on the streams?

During the trials, we’ll do a mix of tests within the water treatment plant and in the streams. This includes testing for dissolved aluminium in water. These tests will be at regular intervals, and each time we need to adjust the amount of PACL we’re using.

Have PACl trials started?

As at 5 February 2020, PACl trials have not yet started. We will give landowners at least 48 hours notice before beginning the trials.

Why are you trialling PACl at all 10 intakes?

1. Trialling PACl at all sites will enable us to capture information specific to each intake site;

2. Treatment, including PACl use, needs to be applied at a whole of network level to achieve its benefits — improved public water supply quality; and

3. We are able to manage and monitor the trials to mitigate any potential environmental impact.

-9 Feb 2020: What happens when we commission Te Mato Vai? Te Mato Vai PMU.

Chemical coagulation is not the only method of achieving water quality standards. The WHO recommend for treatment to be based on source water quality. If the proposed chemical treatment is determined to be inappropriate or unnecessary, then a different method should be investigated.

Recording information from each site will no doubt be beneficial. Perhaps unique to Rarotonga is proposing to proceed with live operation — prior to confirming the appropriateness of the treatment method. However, collection of baseline/control source water quality data is accepted scientific method. Assessing the efficacy of the new three-stage physical filtration process; across all three flow conditions; will either confirm, or counter the stated need for chemical coagulation.

Data on the effectiveness of the physical filtration has been requested from To Tatou Vai in Dec 2019. Receipt of request has been provided, but no data at 7 May 2020.

Where ‘potential environmental impact’ is of concern, a trial should be limited and strictly controlled. The EIA requesting a permit to conduct such a trial would need to propose appropriate environmental monitoring — not just of changes in aluminium levels, but of impacts on biodiversity. The affected communities may also raise objection to being subject to the by-products of chemical experimentation.

Undertaking a concurrent, six-month trial across 10 isolated sites when water flow conditions are highly–variable is a ‘novel’ (risk)-management strategy.

Process for Te Mato Vai (TMV) one off water treatment plants disinfection and PACL dosing trial

The GHD engineering description (above) introduces logistical complexity; when the disinfection wastewater is to be stored onsite until the chlorine levels have decayed; and water treated with PACl is to be tested by To Tatou Vai prior to release into the public water supply network.

- some waterworks have no storage tanks to hold disinfection water;

- tanks storing disinfection water are not available for holding PACl-dosed water pending To Tatou Vai sign-off.

- without remote monitoring or controls, dosing will only be as ‘good’ as the last visit to the intake.

Dosing of PACl commenced 28 Sept 2020 at the Ngatoe water treatment facility; see PACl Trial Data.

Classification/subjects: Te Mato Vai, To Tatou Vai, coagulation, flocculation, water treatment residuals, polyaluminum chloride, PAC, PACL, water standards, water quality, Rarotonga, Cook Islands, South Pacific, environmental impact assessment.

References and Further Reading

See also

- Te Vai Ora Maori - Facebook Page

- Cook Islands Chlorination References, Rarotonga

- Te Mato Vai Disinfection: Chlorination, Rarotonga

- Chlorination: Environmental Impacts – Rarotonga, Cook Islands

- Rarotonga Water Quality Monitoring Data

- Water Treatment Systems: Chemicals and Pathogens

References

- Environment Act 2003. PacLII.

“Inland waters” means the waters and banks of any stream, river, or lake together with the bed (whether dry or not) of any stream, river or lake (for the purposes of this definition “bank” shall include all that area of land extending away from the stream, river, or lake and measured at right angles to a distance of 5 metres from the bank of that stream, river and lake); - Cook Islands National Environment Service (NES): Specific Areas of Concern. -Accessed 2 Dec 2019.

- Te Mato Vai Project Raw Water Quality Review Rarotonga (2014). Watercare New Zealand.

- Polyaluminum Chloride Safety Data Sheets: Chempro, Ixom, ICL, Anchem, GEO.

-

Aluminum/Aluminium Compounds: Human Health, Animal Toxicity, Environmental Fate (Toxnet)

Peer-reviewed research index. -

Aquatic Life Criteria – Aluminum/Aluminium. United States Environmental Protection Agency, 2018.

“The recommended aquatic life criteria for aluminum in freshwater depend on a site’s water chemistry parameters. … The criteria are calculated based on a site’s pH, total hardness, and dissolved organic carbon (DOC).”

- Fact Sheet: Final 2018 Aquatic Life Ambient Water Quality Criteria for Aluminum in Freshwaters - Management of Water Treatment Plant Residuals in New Zealand: Handbook. Sept 1998.

Overview of waste storage, treatment and disposal methods. - Guidelines for Drinking-water Quality Management for New Zealand (Updated June 2019). New Zealand Ministry of Health, 2019.

(PDF) Chapter 13: Treatment processes, coagulation - (Ireland) EPA Drinking Water Advice Note No. 15: Optimisation of Chemical Coagulant Dosing

at Water Treatment Works. June 2014.

Determining appropriate dosing of PACl requires historical water quality data to determine an appropriate equation (algorithm). The algorithm is used to calculate the appropriate chemical dose based on measurement of the current raw water quality.

For water sources where raw water quality changes slowly, manual control of dose may be appropriate and cost-effective, and the algorithm may be used by operators to guide them to the correct dose. For sources subject to rapid change (e.g. direct abstraction from rivers) automated control may be appropriate, and the algorithm may be implemented to provide such control. - Alum Sludge Reuse Investigation Working Technical Report. GHD (Australia). August 2015.

- Guidelines and Good Practices For Water Treatment Residues Handling, Disposal And Reuse in South Africa. S Mokonyama, et al, Umgeni Water. Dec 2017.

- Enhanced Coagulation of Low Turbid Water for Drinking Water Treatment: Dosing Approach on Floc Formation and Residuals Minimization. Jr-Lin Lin and Aldeno Rachmad Ika. Environmental Engineering Science Vol. 36, No. 6. June 2019.

Polyaluminum chloride (PACl) is a commonly used type of hydrolyzed coagulant in the water treatment process. Operators usually applied overdosing of coagulants to reduce turbidity … but resulting in excessed residual Al in finished water more than the limit of drinking water standard. High level of aluminum in the human body is known to have negative effects toward the brain, especially in conditions such as Alzheimer’s disease and dementia (Kawahara and Kato-Negishi, 2011; Killin et al., 2016). Aluminum as a potent neurotoxin can accumulate in the human body and has side effects such as memory loss and impaired coordination (Yasui et al., 1997); in addition of its immunotoxicity effect to the human body (Zhu et al., 2014). - To Tatou Vai: Code of Practice for Design and Construction of Water Supply Infrastructure. Aug 2019. To Tatou Vai Ltd.

- Terms of Reference for PACL use EIA. GHD Memorandum, Oct 2019.

- Information to support approval to commission Te Mato Vai Stage 2. GHD. Nov 2019.

Landowner information pack. - Pacific Organic Standard. Secretariat of the Pacific Community, 2008.

PoetCom Guideline: Chemically treated potable water in crop production, 2020.

News

- 31 Oct 2019: Pipelayers to be held to highest standards. Losirene Lacanivalu, Cook Islands News.

Government confirmed yesterday that it had awarded an $11.2 million contract to local company Land Holdings Ltd to redo substandard pipework.

The replacement of 17km of botched pipeline – a third of those laid by the China Civil Engineering Construction company – is expected to take eight months to complete. - 30 Nov 2019: Govt turns on filtered water to homes. Anneka Brown, Cook Islands News.

After last minute talks with land-owners went right down to the wire yesterday, the Government has instructed contractor McConnell Dowell to begin turning on the taps.

Most land-owners of the 10 water intakes have agreed to a six-month trial of poly-aluminium chloride, a coagulant that cleans the water of smaller particles and harmful protozoa, like those that cause Giardia. - 3 Dec 2019: Turn-on is a turn-off. Anneka Brown, Cook Islands News.

Furious Matavera resident Renall Vogel joined anti-chemical group Te Vai Ora Maori yesterday to protest government turning on the taps of the new filtered water intakes.… The Matavera water plant and pipes will, however, be flushed with chlorine to disinfect the new infrastructure, before it is washed out and the new water supply is switched on.…The water engineers will also begin a six-month trial of poly-aluminium chloride… - 4 Jan 2020: The water debate continues. Te Ipukarea Society in Cook Islands News

Flocculation is a process of settling out particulate matter, for example dirt, from the water. Given that PACl is a chemical that produces a potentially toxic sludge as a byproduct of the flocculation process, this trial needed to be properly assessed for environmental impacts before it was approved.

Another purpose of an EIA is to look at alternatives that may have a lesser negative impact. Therefore, from an environmental perspective, the logical thing to do to reduce dirt getting into the water is to first trial alternatives which provide a lower level of risk to our freshwater ecology. - 15 Jan 2020: To Tatou Vai makes progress with Environmental Impact Assessment. Media Release.

The EIA will advise as to potential effects of the by-products – sludge and discharge water from the coagulation, flocculation and sedimentation as part of the designed water treatment process for the Te Mato Vai project. - 24 Jan 2020: Something in the water. Moana Makapelu Lee, Cook Islands News.

Ecologists have this week begun an ecological survey of the streams flowing through Te Mato Vai’s water intakes. The study includes a wide spanning survey of the aquatic habitat and wildlife populations as well as the stream conditions. Information gathered will contribute to the Environmental Impact Assessment report commissioned by Rarotonga’s water supplier, To Tatou Vai… Leading the study are aquatic ecologists Dr Natalie Clark and Lauren Pratt, who are employed by GHD New Zealand, which is engaged by the Cook Islands Government to deliver and manage Rarotonga’s new water facilities. - 31 Jan 2020: Cook Islands water system EIA ‘too narrow’ Te Ipukarea Society / Radio New Zealand News.

“After talking to the consultants [Tonkin and Taylor] this EIA is only looking at the use of polyaluminium chloride…it’s not looking at chlorination and they may as well do the whole thing all at once…The EIA is not really looking at alternatives, it’s merely looking at the impacts of the PACl and how these may be reduced or mitigated on the assumption that PACl will be used.”

-Kelvin Passfield - 9 Feb 2020: What happens when we commission Te Mato Vai? Release, Te Mato Vai PMU.

- 18 Feb 2020: Why only collecting stream water when the water is running ‘clear’ is not an option Release, Te Mato Vai PMU.

There are good reasons why turbidity detection and diversion systems are not a viable alternative to PACl. The option to bypass the intake during wet weather events is impractical and detrimental for three reasons:

1. PACl dosing is still required for treating ‘clear’ water flows.

2. Collecting water when the streams are in high flow (generally during heavy rain) will help prevent public water supply shortages.

3. An effective bypass system would most likely need a permanent power supply at each intake site. - 19 Feb 2020: Chemical water trial is ‘lawful’. Losirene Lacanivalu, Cook Islands News.

[To Tatou Vai CEO] Manning said the initial work was lawful. “This has been agreed with landowners through a consultative process, noting however that there is some opposition to the use of water treatment chemicals, but that doesn’t necessarily make it unlawful.” -

21 April 2020: How does polyaluminium chloride (PACl) work. Te Mato Vai PMU.

We need to use PACl in Rarotonga because stream water contains high levels of contaminants — everything from bird poo to leaves and soil. This is true for water taken from streams, rivers or lakes around the world, not just in Rarotonga. Even stream water that looks clear still contains harmful protozoa and bacteria too small for people to see. - 2 May 2020: Andy Kirkwood: Sludge! Letters in Cook Islands News.

A March 2020 expert review estimates the scale of the issue. The use of polyaluminum chloride (PACl) – a chemical that helps to remove dirt during rain – will generate 4,000 cubic metres of chemical sludge each year. - 23 May 2020: Andy Kirkwood: Water treatment: Don’t be hasty Letters in Cook Islands News.

The Government intends to proceed with a separate six-month PACl trial, despite not having a permit to do so. The Government claims the trial is necessary to inform the environmental impact assessment. This claim is not supported by the GHD technical documentation, the Court-expert assessment, or the opinion of the consultancy firm preparing the To Tatou Vai environmental impact assessment submission. The Government’s claim a trial is necessary – is a fiction. - 25 Jun 2020: Turning on the taps Katrina Tanirau, Cook Islands News.

Authorities acknowledge they need to be as transparent as the water they plan to pipe into people’s homes in Rarotonga.…

Storm damage to the main water storage pond meant it had to be reconstructed, and that delayed the project. - 20 July 2020: Complaint filed against Govt . Rashneel Kumar, Cook Islands News.

Deputy Prime Minister Mark Brown said the Government haven’t commenced dosing the public water supply with the coagulant poly aluminium chloride. Brown said they will follow due process by notifying the landowners before any dosing is to proceed. “At this point in time, this is a matter before the court.”

TVOM: “We’ve repeatedly asked our government for information - what are the risks, are all the intakes affected, and have all the faults now been fixed? A permit is required, and the people have a right to be consulted.” - 22 July 2020: Andy Kirkwood: Te Vai Ora Maori- says no permit is an offence. Cook Islands News.

Te Vai Ora Maori now calls for the Minister release the expert finding on the settlement tank overflow fault, and details of the “storm damage” that was sustained by the main water storage pond in June.

Both the settlement tank and storage pond are part of the PACl dosing system. Similar faults may affect all 10 of the Te Mato Vai waterworks, and risk impacts on the health and safety of residents living downstream. - 20 Aug 2020: Water treatment: ‘No one is above the law’ . Rashneel Kumar, Cook Islands News.

…a body corporate is liable for a fine of $100,000, Flanagan said. There is also provision for a further fine of $10,000 for each day the offence continues, she added.

“There are 10 intakes – that’s 10 offences. We are seeking expert advice on whether the respondent should be the Cook Islands government, GHD, McConnell Dowell – or all three. No one is above the law, not even government. We have prepared a legal brief; and invite anyone interested to get in touch.” - 24 Aug 2020: Activists claim Cook Islands Govt set to illegally use chemicals in water. RNZ.

The Cook Islands News reported the group alleged last month, in a complaint to the National Environment Service, that the government was dosing the water supply with a chemical coagulant without a proper permit.

The group said its complaint is not about the science of water treatment, but about the “regulatory process”.

Earlier this month To Tatou Vai, the authority being set up to run the scheme, wrote to landowners saying it was about to start a six month trial using the coagulant. - 5 Sept 2020: Water dosing ‘trials’ starts . Katrina Tanirau, Cook Islands News.

The government says poly aluminium chloride trials for the next six months will allow for making better-informed decisions about the future of Rarotonga’s public water supply, but opponents say proceeding with the trial is irresponsible. - 5 Sept 2020: Te Mato Vai water system one step closer to delivering safe and reliable drinking water. Cook Islands government, Cook Islands News.

“As I have already confirmed, permits are in place for the construction and commissioning of the Te Mato Vai Stage Two project. The Cook Islands Government has committed to managing the PACl trials in a way that protects the health of our community and environment and provided all reassurances necessary that the use of chemicals during the commission will not cause significant environmental harm or breach any requirements of the Environment Act 2003.”

-Nga Puna, Director National Environment Service - 8 Sept 2020: Water issue. Justine Flanagan in Cook Islands News.

Statements attributed to the director of NES (National Environment Service) are deliberately evasive. He confirms that Te Mato Vai have a permit for “construction and commissioning”. He does not state that the permit covers the use of PACl. - 29 Sept 2020: A step closer to ‘cleaner drinking water’. Cook Islands News.

The first dosing of poly aluminium chloride (PACI) to the settling tank took place at the Ngatoe water intake yesterday.

Following “extensive consultation”, PACI dosing was witnessed by the National Environmental Service, landowners and Aronga Mana prior to the milestone being marked by government officials and other dignitaries. - 29 Sept 2020: Andy Kirkwood: The many hats of GHD. Cook Islands News.

In effect, a New Zealand company is both proposing; and then self-approving the use of a chemical that industry guidelines do not recommend. Without environmental monitoring, damage to Rarotonga’s stream ecosystems will go undetected.

The reality of chemical-use is that it generates chemical waste. The reality of water technicians, is that they’re not freshwater ecologists.

Working Draft. Updated: 19 Oct 2020.